Safety requirements for tires and tower cranes

2021-05-02

Tire crane safety operation requirements:

(1) When the crane is in operation, the outriggers must all extend out and be padded. When rotating, the rotary clutch should be smoothly engaged to reduce the weight swing.

(2) The telescopic boom is forbidden when loading. When lifting the boom, it should move slowly.

Crane crane safety operation requirements:

(1) The laying of roadbeds and tracks for cranes must be strictly in accordance with the original regulations. Both sides of the roadbed should have good drainage measures; the gauge deviation should not exceed 0.1% of the nominal value , and horizontal tie rods should be installed every 6m between the two tracks. The slope of the top surface of the rail in the vertical and horizontal directions shall not exceed 0.1% ; the track joints shall be staggered, the gap between the rail joints shall be 3 to 6mm , and the joint shall be greater than the radius of the travel wheels. Earthing of the track should be reliable and the grounding resistance should be no more than 10 ohms.

(2) After the installation is completed, the vertical deviation of the tower body shall not exceed 0.3% under the condition of no load. The weight of the tower shall comply with the original regulations.

(3) When multiple cranes are working on the same work surface, the safe distance between the two machines shall not be less than 5m .

(4) Each transmission mechanism of the crane should work normally, the brakes should be sensitive and reliable, and the rail clamping device should be intact. The steel wire rope should meet the crane design standard, and the length should meet the requirements for use. The winding on the drum should be arranged neatly. Lifting mechanism steel wire rope, when the hook is at the lowest position, the wire drum should retain at least three coils of wire rope.

(5) Various indicators, ammeters, and voltmeters in the crane control room are all in good condition. Machines should be equipped with signal devices, such as bells, horns, etc. When the height is above 45m , additional altitude indicators, anemometers, amplitude indications, and weight indication devices should be added.

(6) The crane must be installed with walking, luffing, hook height, and torque limiter. Cranes equipped with lift cabs shall be equipped with cab upper and lower height limiters and broken rope safety devices. Various devices should be sensitive and reliable.

(7) The distance between the attachments of the attachment crane and the distance from the wall should be set according to the original regulations. And make the necessary structural recalculation of the building.

(8) After the work is completed, the crane should be parked in the middle of the track, the boom should be turned to the downwind direction, and the swing brake should be relaxed. The trolley and balance bar should be turned to the downwind direction, and the swing brake should be loosened. The hook should be lifted up to 2 to 3m away from the top of the boom and the rail clamp should be locked to fix the crane and the track. In case of over 8 winds, the upper part of the tower shall be pulled with four wind ropes and ground anchors.

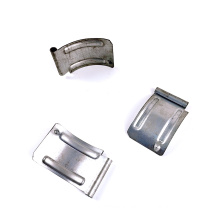

A tower crane anchorage frame is a structural component used to secure a tower crane to the ground or a building during its operation. It is typically made of steel and designed to withstand the high loads and forces exerted by the crane.

The anchorage frame consists of a base plate or foundation, which is securely attached to the ground or building structure. It also includes vertical support beams or columns that provide stability and strength to the frame. These columns are connected to the base plate and extend upwards to support the tower crane.

The anchorage frame is designed to distribute the loads from the crane's operation evenly and safely to the ground or building structure. It must be able to withstand the weight of the crane, the loads lifted by the crane, wind forces, and other external factors.

The design and construction of a tower crane anchorage frame must comply with local building codes and regulations. It is typically engineered by a structural engineer to ensure its strength and stability.

Proper installation and regular inspections of the anchorage frame are essential for the safe operation of a tower crane. Any signs of damage or deterioration should be addressed immediately to prevent accidents or structural failure.

Jacking Part Anchorage Frame, Tower Crane Anchorage Frame, Mast Section Anchorage Frame, Anchorage Frame For Tower Crane, Tower Crane Anchor

Deep Drawing Parts,Electric Terminal Co., Ltd. http://www.sytopkittowercrane.com